Ever wondered how Hamilton manages to keep your local wholesalers stocked with its core trade ranges, such as the popular Sheer and Hartland ranges? Crafting Hamilton’s high-quality decorative wiring accessories at its Bristol manufacturing facility involves tried and tested processes that ensure durability and reliability. Curious to see how it’s all done?

Welcome in! Click here to watch the video tour for an exclusive sneak peek into Hamilton’s 35,000 square foot factory…

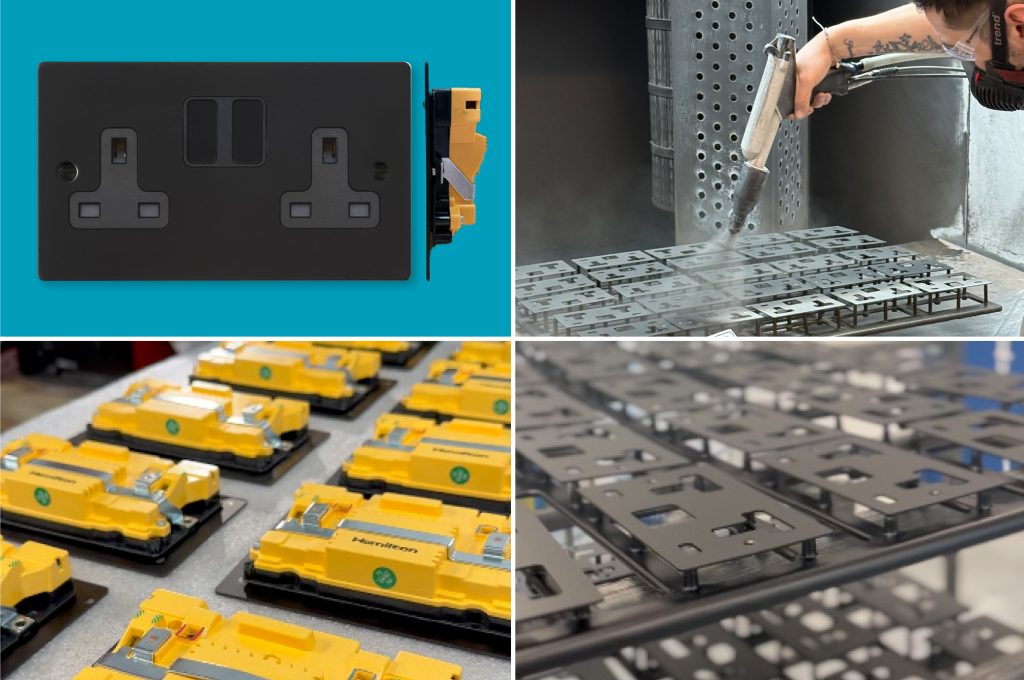

Laser Cutting: It all starts with precision. Hamilton’s materials are expertly cut using state-of-the-art laser technology, ensuring the accuracy and consistency of every plate.

Plate Preparation and Powder Coating: Once cut, Hamilton’s plates undergo thorough preparation before being coated with a durable powder coated finish. This not only enhances their appearance but also provides long-lasting protection against wear and tear. They’re then baked in Hamilton’s specialised ovens, securing durability. USB Sockets are then etched with outputs in accordance with British Standards.

Quality: Hamilton’s Quality Management System (QMS) is accredited to BS EN ISO 9001 : 2015 this ensures all processes in its factories and offices uphold internationally recognised standards.

Testing: Safety is non-negotiable. All Hamilton inserts are designed and manufactured in accordance with specific product standards.

- Sockets are certified to BS 1363

- Switches are certified to BS EN 60669-1

The company’s in-house testing procedures include USB compatibility, full load testing, temperature rise and repeatability.

Assembly and Packaging: The products are assembled, bagged and packed with care, ready to be shipped to customers. Thousands of stock items are produced every day, each one carefully inspected to ensure it meets Hamilton’s stringent quality standards.

Ready to Ship: And there you have it – a glimpse into the intricate process behind some of Hamilton’s wiring accessories. From concept to creation, every step is executed with precision and dedication, ensuring that when you choose Hamilton products, you’re choosing reliability, durability, and quality.

Supporting Your Local Wholesaler, Every Step of the Way. Choosing Hamilton isn’t just about quality craftsmanship – it’s also about supporting its customers. The company’s manufacturing facility in Bristol isn’t just where innovation and precision thrive; it’s also where Hamilton ensures your local wholesaler stays fully stocked with the products you need and trust.

For more from Hamilton click here.