The long-standing uncertainty surrounding zinc whiskers faced by end users and contractors across the UK can now be mitigated when installing a Univolt Basor wire basket.

Using a special acidic galvanising process, any presence of whiskers is now a thing of the past.

Steve Davis, National Business Development Manager of Univolt explains, “Zinc whiskers essentially grow on steel surfaces that have been finished with an ordinary coating of Zinc to prevent corrosion, however, it can expand potentially forming the damaging whiskers.

“There are various types of zinc processes where whiskers can grow, however, Univolt Basor baskets can avoid this by using a special process which negates the growth of zinc whiskers. Under laboratory conditions a test sample of wire basket was continually monitored over a 16 month period using an electron microscope at a magnification of 400X which indicated no presence of whiskers during the entire test.”

“Minimising any issues surrounding zinc whiskers marks one of the many added benefits for users opting for the Univolt Basor wire basket range, eradicating any confusion between finishes i.e. powder coated, pre-galv, or stainless steel, which can add to project costs, or longer lead times.”

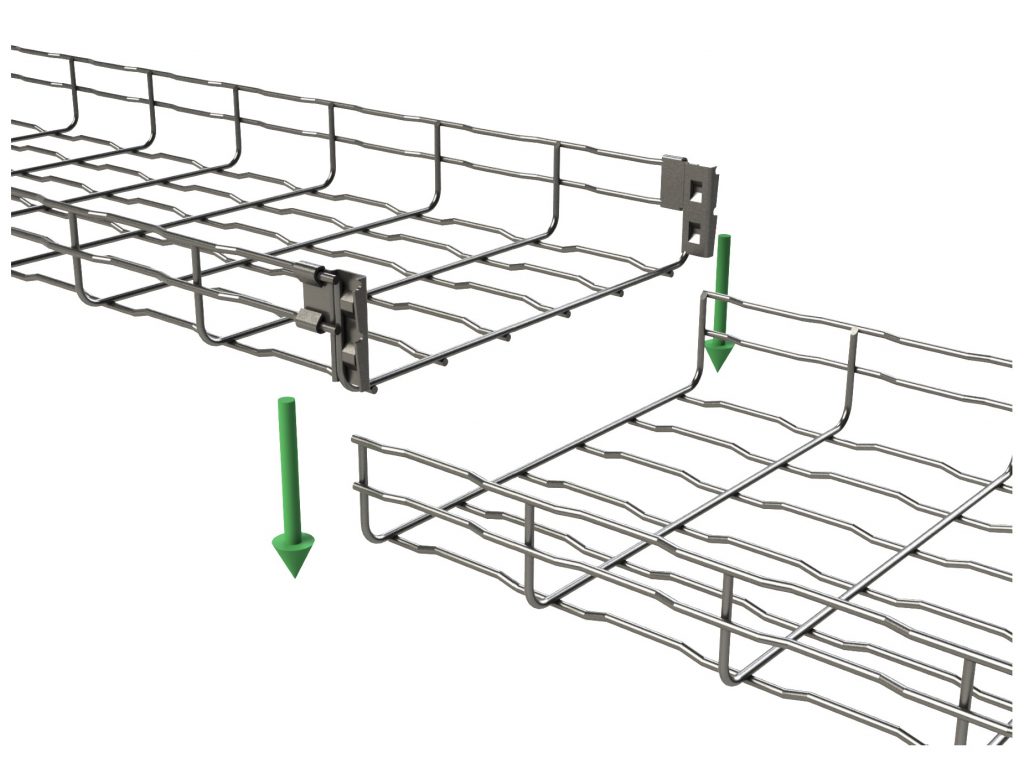

As part of a complete wire basket solution, Univolt offers a range of quick fit self-coupling wire baskets and accessories to speed up, enhance and secure on site in seconds rather than minutes. Products are available in a range of sizes from 35mm, 65mm and 105mm in depth and from 60mm- 600mm in widths.

Steve continues, “The addition of a full wire basket range helps us complete our cable containment range, ensuring specifiers, contractors and wholesalers can confidently work with us, utilising Univolt as a one stop shop for all cable containment needs.”