Cellforce and Siemens have concluded a memorandum of understanding with the aim to enter a strategic partnership. Cellforce develops and manufactures high performance Li-ion battery cells for the automotive market by utilising advanced battery materials and production technologies.

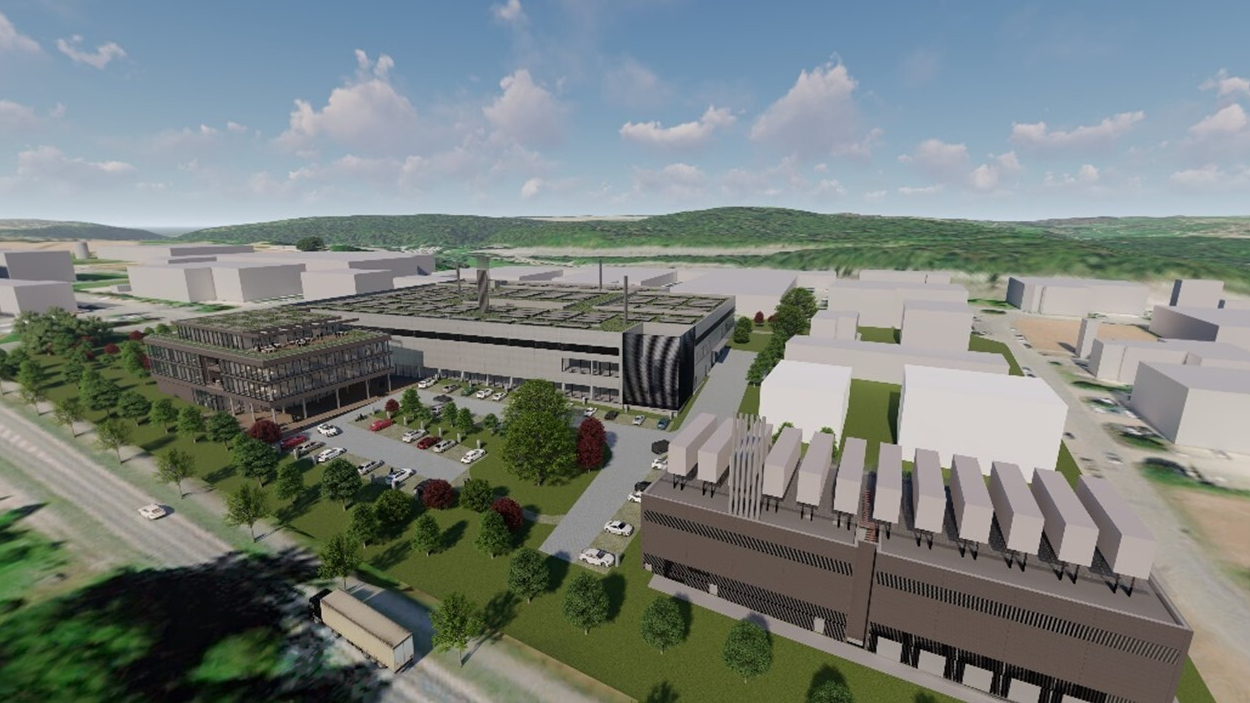

Siemens will become Cellforce’s preferred supplier in automation and digitalisation technology, speeding up the completion of the Cellforce gigafactory in Reutlingen, Germany. Both companies will join forces to enhance battery design, manufacturing processes and building operations, from production design, planning and simulation, to the automation of the entire production process.

Both companies will also work together to create a sustainable, comfortable and safe working environment with Siemens building management technology and energy performance services.

Siemens will provide a broad range of solutions from the Siemens Xcelerator portfolio, including Product Lifecycle Management (PLM), Manufacturing Execution Systems (MES), industrial edge computing, and tools for IT/OT connectivity, fire safety and security, measurement and control technologies to enhance energy optimisation for the carbon net zero battery cell factory.

Siemens’ end-to-end solutions will support Cellforce to produce high performance batteries at scale, while meeting throughput, cost, and sustainability targets.

“End-to-end digitalisation of design and production is key for a commercially successful battery cell production with the lowest CO2 footprint in Germany,” says Dr. Markus Gräf, COO of Cellforce.