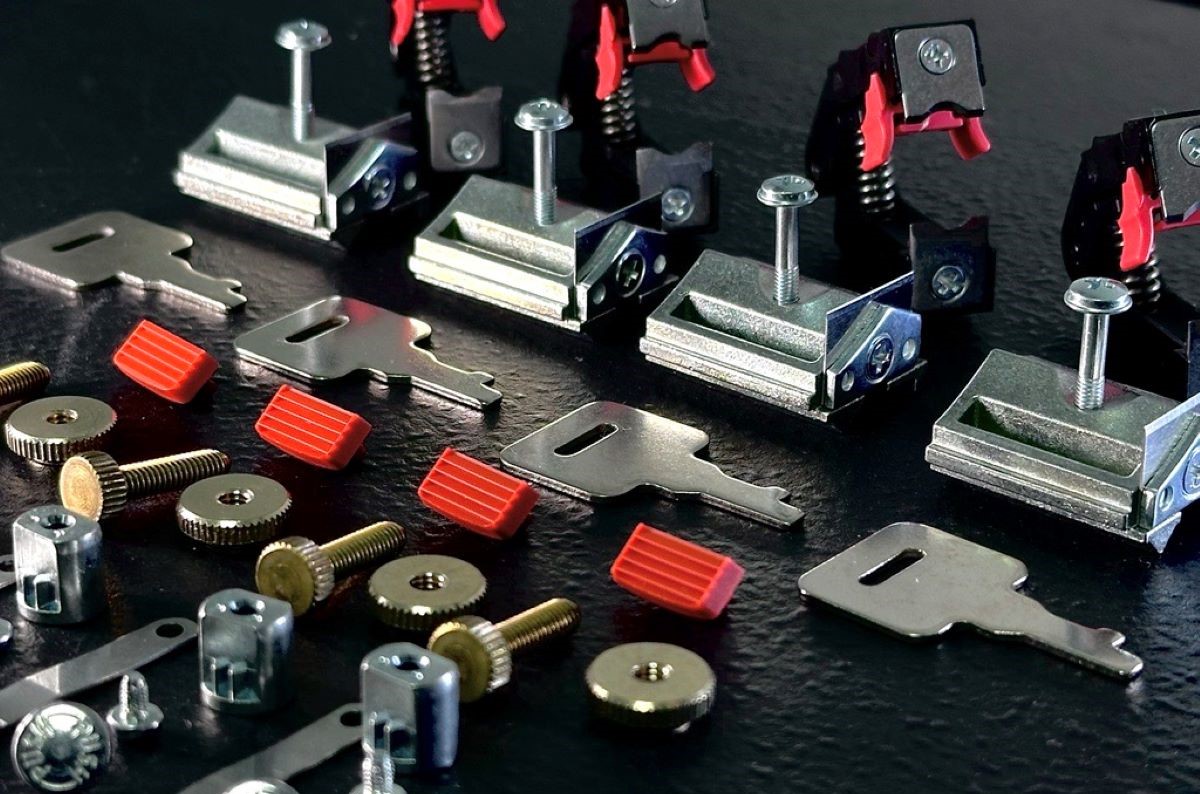

Available through its network of merchants and wholesalers, KNIPEX offers spare parts for many of its tools with interchangeable components so users can maintain the performance of their tools without incurring the cost of complete replacements. Hardworking tools may eventually experience some wear and tear, but that does not mean its life is over. Renewing certain parts of the tools such as blades and push buttons when they wear out is economical, environmentally conscious and easy.

For example, the KNIPEX Self-Adjusting Insulation Stripper is designed to strip wires ranging from solid and multicore to finely stranded conductors. It works well with standard insulation materials and can handle flat ribbon conductors up to 10mm in width. Its sharp blade, made of oil-hardened special tool steel, cuts cleanly through insulation without damaging the wires beneath, a critical factor for maintaining safety and functionality. When the blade eventually needs replacing, it’s quick and convenient to do so with just a screwdriver, so you can always have a sharp blade that makes the repetitive job of cutting through wire easy.

KNIPEX bolt cutters offer a robust design that facilitates simple maintenance. Equipped with non-slip handles, a dozen adjustment positions for precision and induction-hardened cutting edges, they proficiently cut through chains, padlocks, bolts and screws. Maintaining the efficiency and safety of these bolt cutters is straightforward. Users can effortlessly switch out the cutter head when necessary by unscrewing the nuts, replacing the head and securing everything back in place. This quick refurbishment process ensures that the bolt cutters are easily restored to peak condition and ready for the next job.

A pipe cutter that stands out for its sharp blades made from special surgical steel is the KNIPEX BiX. It cuts high-temperature plastic drainpipes and electrical conduits without creating shavings and can trim sealing sleeves flush against walls during final installations. Precision work like this calls for sharp tools, so KNIPEX has integrated not just one, but two spare blades within the body of the tool to ensure that no matter the location or what the user is cutting, the perfect edge is just a quick swap away. For the use of extra blades, there is a set of eight available.

Although it happens rarely, if the push button on the KNIPEX Cobra, the pliers wrench or the KNIPEX TwinGrip Slip Joint Pliers becomes worn, users do not need a new tool – an assortment of spare parts are available. It takes just a few moments to replace the included push button and the pliers are ready for use again.

To read more on KNIPEX, click here.