If you have read any of UK manufacturer of electrical test equipment Kewtech‘s previous articles, you may already be familiar with the mantra “Test Before You Touch”.

In a previous piece, the company explored the risks of metallic surfaces becoming live. Here, it dives into a lesser-known but equally dangerous issue: phenolic breakdown in thermosetting plastics.

What are phenolic plastics?

Back in the late ’60s through the early ’90s, phenolic resin was the go-to material for electrical accessories: strong, heat-resistant, and a great insulator – at least when new.

Fast forward a few decades and those same components could be hiding a serious hazard.

Phenolic materials don’t always age gracefully; over time, heat from loose connections or overloaded circuits can cause them to crack, become brittle, and even carbonise.

What’s more, carbonised phenolic can become conductive. That means what was once a safety barrier can turn into a live path for electricity.

Phenolic plastics are still commonly found in older DNO intake cut-outs, identifiable by the dark brown, almost-black colour.

What to watch out for

Key identifiers include scorch marks, cracks, brittle surfaces, or that tell-tale burnt smell. See the video below for an example:

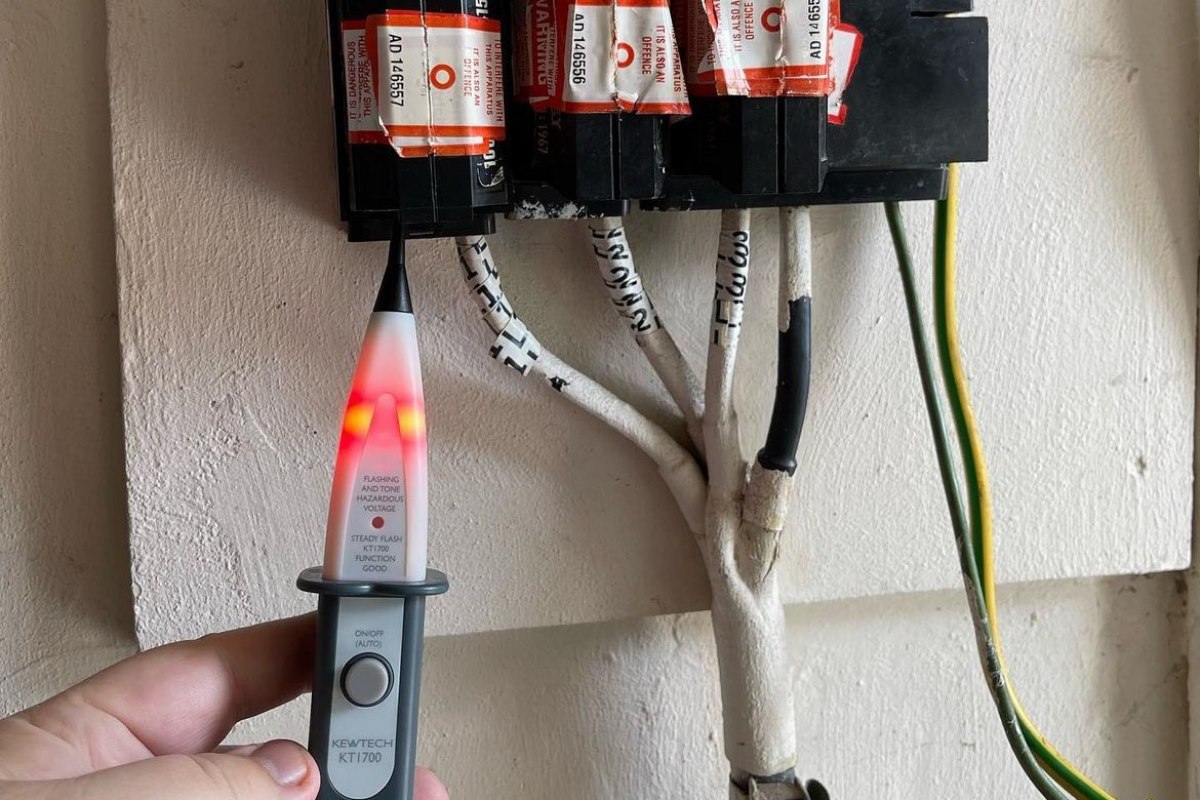

Visual checks are your first line of defence, but tools like the Kewtech KT1700 single-pole voltage tester can give you an early warning.

The tester won’t diagnose phenolic breakdown directly, but it will tell you if unexpected voltage is lurking on nearby cut-out surfaces – a common symptom when phenolic insulation fails.

Lawrence, AKA ‘Bristol Sparky’, comments, “I wasn’t aware of phenolic breakdown, and now it’s one of the first things I check before I go sticking my hands anywhere near anything.

“A cut-out or even a board – if there is suspicion, I use my KT1700 contact voltage tester before I go and touch anything.”

The bottom line

Phenolic breakdown is a silent threat in ageing electrical systems. Combining training, sharp eyes, and smart tools like the KT1700 helps you stay safe, compliant, and ahead of the curve.

Remember: ‘Test Before You Touch’, because what you can’t see can hurt you!

For more information or electrical safety tips, visit Kewtech’s website.

For more from Kewtech, click here.