In2tec, a UK-based sustainable electronics specialist, has introduced new technology designed to make industrial LED lightbars more circular, repairable, and resource-efficient.

The company’s ReUSE and ReCYCLE processes allow lightbars to be fully disassembled and reused, significantly reducing carbon emissions and electronic waste.

Reducing manufacturing emissions and e-waste

As energy costs rise and environmental regulations tighten, LED lightbars have become a mainstay in industrial and commercial applications.

In2tec’s approach takes sustainability beyond energy efficiency by enabling materials and components to be recovered and reused at end-of-life.

“We’re seeing a 62.5% reduction in CO₂ emissions during manufacture compared to conventional PCBAs,” says Emma Armstrong, Sustainable Electronics Ambassador at In2tec.

“And with over 20 million lightbars sold annually, that translates to nearly 3.9 million kilograms of CO₂ saved – every year.”

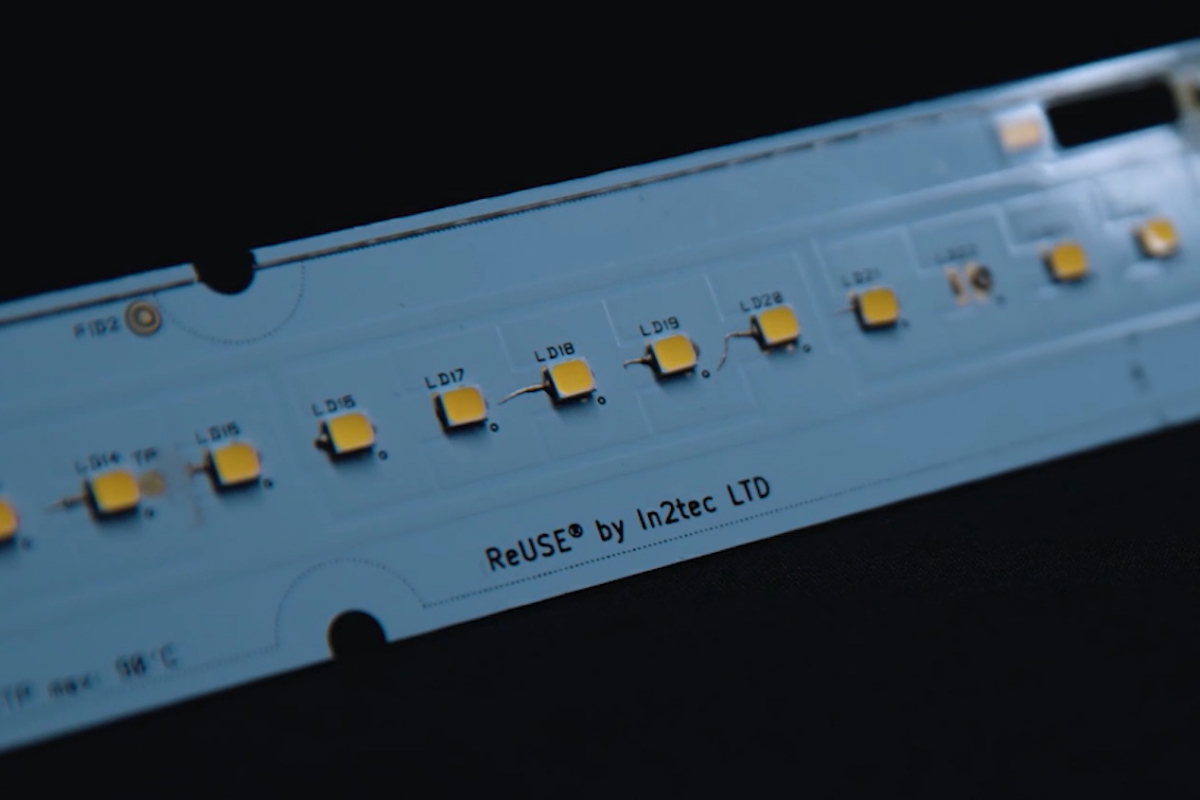

At the core of this approach is ReUSE, a design method that allows printed circuit boards to be separated at end-of-life without damaging components.

Combined with ReCYCLE, a low-energy recovery process, it enables manufacturers to reclaim materials such as substrates and electronic parts for reuse in future production.

This method aims to address one of the biggest sustainability challenges in industrial lighting: the premature disposal of components that could otherwise be repaired or repurposed.

Designed for disassembly and material recovery

Lighting is a major source of global energy consumption and waste. According to UN data, 61.3 million tonnes of electronic waste were generated in 2023.

In2tec’s approach integrates sustainability at the design stage, ensuring that each lightbar can be easily repaired or broken down for material recovery.

Emma continues, “We’re not just reducing emissions; we’re changing how electronics are made and unmade.

“This is about designing lighting systems that work for the planet, not just the bottom line.”

ReUSE technology is compatible with both traditional and alternative substrates, including FR4, PET, and aluminium.

According to In2tec, it achieves bond strengths close to solder while operating at significantly lower temperatures, reducing energy use during manufacture and recycling.

For manufacturers, potential benefits include:

• Reduced production emissions

• Lower energy consumption during manufacture

• Improved repairability and reuse

• Greater material recovery and resource efficiency

• Support for compliance with WEEE and sustainability standards

With more than 25 years of experience in flexible electronics, In2tec says it continues to explore ways to embed circular design principles into manufacturing.

Its ReUSE and ReCYCLE technologies aim to reduce environmental impact and extend the life of industrial lighting systems.