By Chaz Andrews, Technical Manager of Doepke UK

Effective RCD protection for electric vehicle (EV) sockets relies on the correct specification of the associated EV charging equipment and the RCD. Don’t leave it until the installation is being tested to understand the revised requirements. Amendment 1 – 722.531.3.101 relates to Mode 2 and 3 charging equipment standards. For Mode 4 charging equipment, refer to the manufacturer’s recommendations for RCD selection.

Background Product Standards

Product reference standards for Mode 2 and Mode 3 charging equipment covering 6mA DC fault current detection, enabling the safe use of Type A or F RCDs upstream, changed in 2018.

When selecting charging equipment, check that the appropriate standard / edition applies to the product you are purchasing.

IEC 62752: In-Cable Control and Protection Devices (IC-CPD) for Mode 2 charging cables.

Updated in 2018, to include a 6mA DC detection and switching feature within the IC-CPD.

IEC 62955: Residual Direct Current Detecting Devices (RDC-DD)* for Mode 3 charging.

New standard published 2018 defining product formats and performance requirements.

*Doepke Technical Publication 18, dated October 2018 (available online), gives further detail.

Amendment 1 clause 722.531.3.101

RDC-DDs & IEC 62196: Are generally associated with Mode 3 charging. However, there are instances where this feature may have to be provided separately for Mode 2 charging cables, if they do not include 6mA DC detection – see Mode 2 charging below.

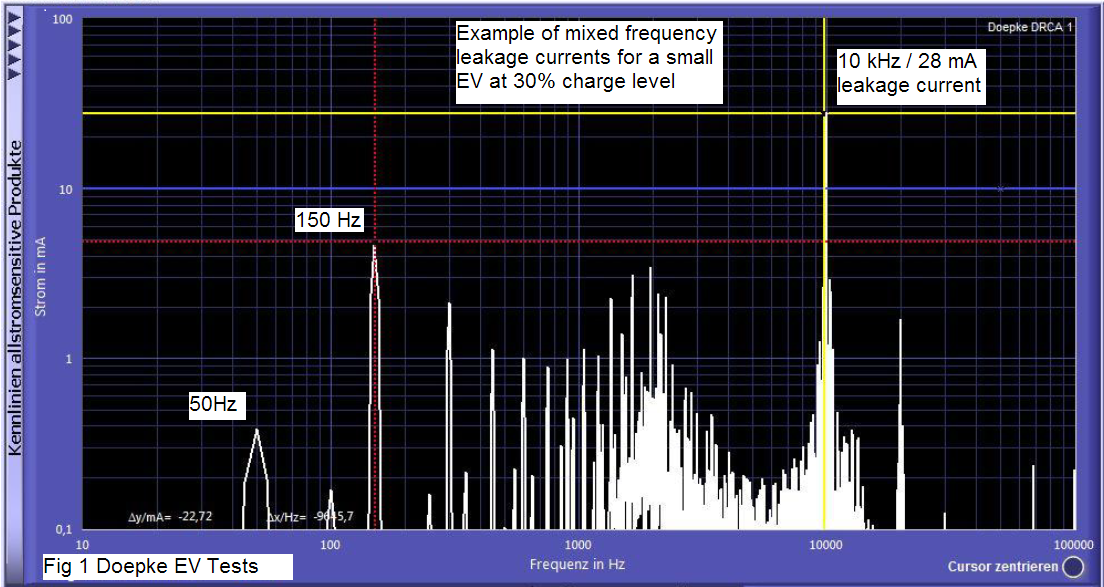

Type F RCDs: Refer to (ii) and Note 3 under 722.531.3.101. Certain designs of EV battery charging technology, produce mixed frequency leakage currents – see Figure 1 (at the top of this page) to see Leakage current tests performed on a small EV.

In this example, the majority of the leakage current is generated at frequencies greater than 50Hz. High frequency leakage currents can saturate Type A RCD magnetic circuits, resulting in a change to the tripping characteristics. Refer to the EV manufacture for advice on RCD selection.

Mode 3 Charging

Manufacturers of Mode 3 charge points can include an RDC-DD in the charge point, or recommend an alternative solution, external to the charge point -see (ii) and Note 3. For example, Tesla specify the use of an AEV RCCB for use with their Mode 3 chargers.

RDC-DDs manufactured to IEC 62955, for use with separate RCDs, must operate within 10s at 6mA DC. They must not operate when subjected to an AC residual current of 30mA. In the event of someone touching a live conductor and earth, the associated 30mA RDC must operate first and electrically isolate the circuit i.e. an RCD-DD operating a standard contactor in a Mode 3 charge point, does not provide electrical isolation. Doepke’s Type A-EV has been independently certified by VDE to IEC 62955 and provides 30mA protection for use in Mode 3 applications, providing effective isolation.

Mode 2 Charging

IC-CPDs used in mode 2 charging cables, manufactured to IEC 62752 – 2018, should include a 6mA smooth DC detection / disconnection feature. Refer to the labelling on IC-CPD or the manufacturer’s information to check that the cable includes this feature.

A single Mode 2 charging cable incorporating 6mA smooth DC detection can be safely connected to a circuit protected by a Type A or F RCD. For Mode 2 charging cables that do not include this feature, a Type AEV or Type FEV RCCB can be used to provide the required level of protection – as per clause 722.531.3.101 (ii).

Understand → Check → Specify → Purchase → Install → Test → Sign off

Effective RCD protection for an EV socket relies on the correct specification of the associated EV charging equipment and the RCD – see BS7671 clause 133.1.1 , 2 and 3. If you specify and purchase incompatible equipment, it may not become apparent until the testing and sign-off phase.

Testing a 30mA RCD to verify the tripping characteristic is common practice. There are conflicting views relating to the need to test the RCD-DD feature. It may be appropriate and reasonable to test / verify this feature during commissioning, as it has a direct impact on the ability of the associated RCD to perform its safety function. The 6mA test feature included in test instruments suitable for testing / commissioning EV installations is a simple test, and if the RCD-DD is working correctly, should only add minutes to the time to test.

Conclusion

The selection of any associated RCD ‘Type’ should take the following into account. Certain EVs may have specific charging requirements – for private installations, refer to the EV manufacturer’s information before you quote for the job. Charging Mode 2 or 3? Check that the features you expect to get in the charging equipment are provided in that version and the associated RCD is the correct type.

Equipment that fails to meet the revised regulations creates a hidden danger, as it will not provide the expected level of protection. Check before you purchase and install.

For more information, visit www.doepke.co.uk or email sales@doepke.co.uk